The influence of the accuracy of reproducing the uniaxial tensile test of mild steel in the H-M plasticity model on the behaviour of a perforated thin walled shell subjected to compression

1

Faculty of Civil Engineering, Warsaw University of Technology, Poland

Submission date: 2024-05-09

Acceptance date: 2024-05-28

Publication date: 2025-06-16

Corresponding author

Andrzej Michał Piotrowski

Faculty of Civil Engineering, Warsaw University of Technology, Al. Armii Ludowej 16, 00-637, Warsaw, Poland

Faculty of Civil Engineering, Warsaw University of Technology, Al. Armii Ludowej 16, 00-637, Warsaw, Poland

Archives of Civil Engineering 2025;71(2):209-224

KEYWORDS

TOPICS

ABSTRACT

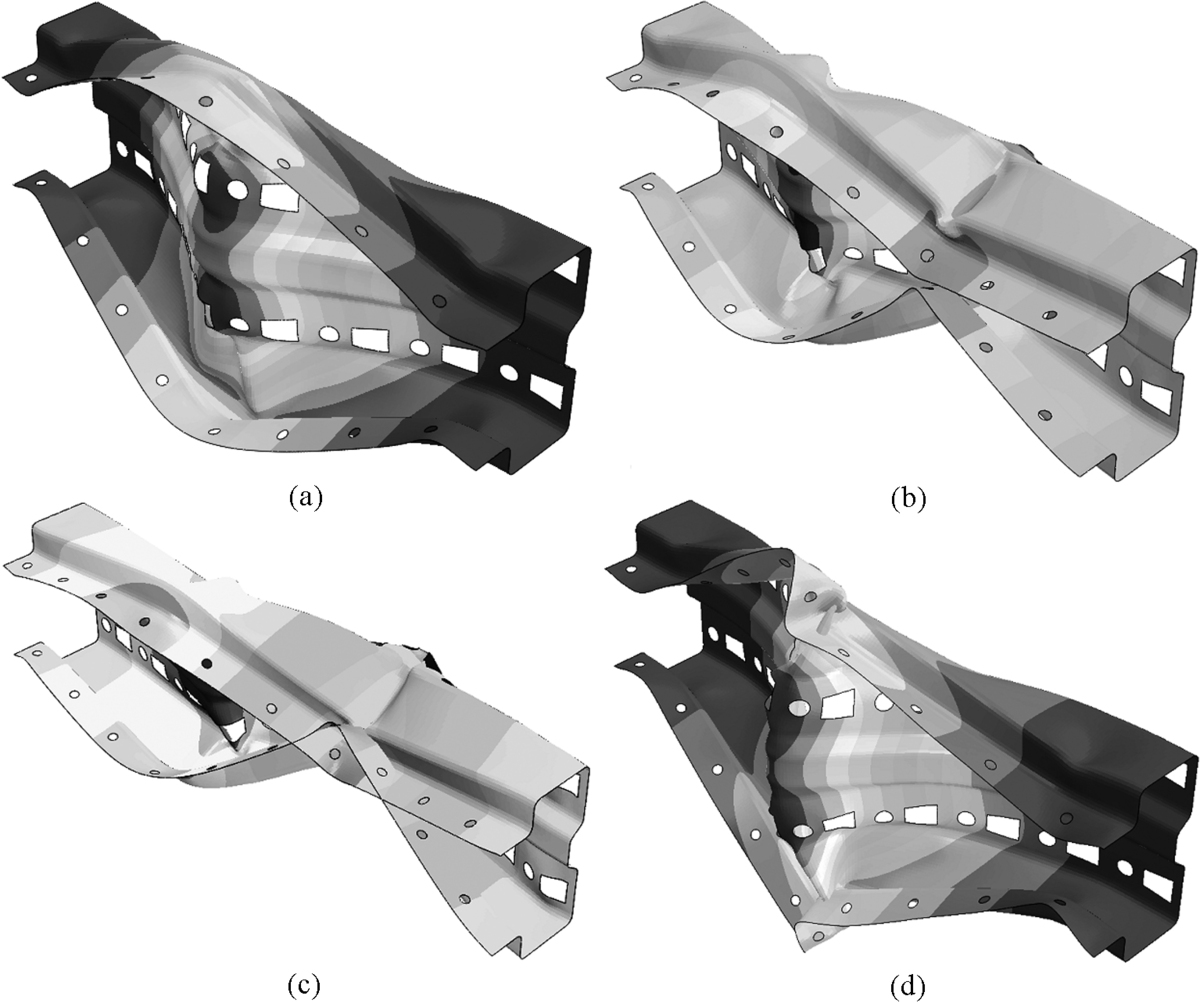

The article describes the impact of modeling the plasticity constitutive relationship on the buckling of a short section of a perforated thin-walled steel bar with an open cross-section (modeled as a perforated shell) subjected to compression, being one of the elements of a high-storage system. Numerical calculations were performed in the ABAQUS/Standard program with application of the elasto-plasticity theory of large deformations with additive decomposition of the logarithmic strain tensor and taking into account the nonlinear isotropic or kinematic strain hardening models. The isotropic nature of the material was considered and the plastic flow law associated with the Huber-Mises plasticity condition was assumed. In the elasticity range, linear characteristics of the material was assumed, while in the plasticity range, the shape of the uniaxial strain hardening curve was described as piecewise linear approximation of plastic strain-stress graphs obtained from uniaxial tensile tests. The 24 sets of material data obtained on the basis of experimental tests were analyzed and the influence of differences in the values of material parameters were described (in tests carried out on samples cut from the modeled bars, large differences were found in the values of material parameters and the shape of uniaxial tension graphs). Also the accuracy of strain hardening modeling (the number of sections assumed in the model piecewise linear) on the calculated bearing capacity force value was considered and evaluated.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.