Mechanical properties and fracture behavior of sandstone similar materials with different joint positions and thicknesses based on triaxial testing and PFC simulation

1

State key Laboratory of Mining response and disaster Prevention and Control in Deep Coal Mines, Anhui University of Science and Technology, China

2

School of Civil Engineering and Architecture, Anhui University of Science and Technology, China

3

Civil Engineering Post-doctoral Research Worktation, China MCC17 Group Co.,LTD., China

Submission date: 2023-12-21

Final revision date: 2024-02-23

Acceptance date: 2024-04-16

Publication date: 2024-12-11

Corresponding author

Wei Jing

State key Laboratory of Mining response and disaster Prevention and Control in Deep Coal Mines, Anhui University of Science and Technology, China

State key Laboratory of Mining response and disaster Prevention and Control in Deep Coal Mines, Anhui University of Science and Technology, China

Archives of Civil Engineering 2024;70(4):615-629

KEYWORDS

mechanical propertiesjointed rock massdifferent thicknesses and positions of jointsspatio-temporal evolution of cracksPFC simulation

TOPICS

ABSTRACT

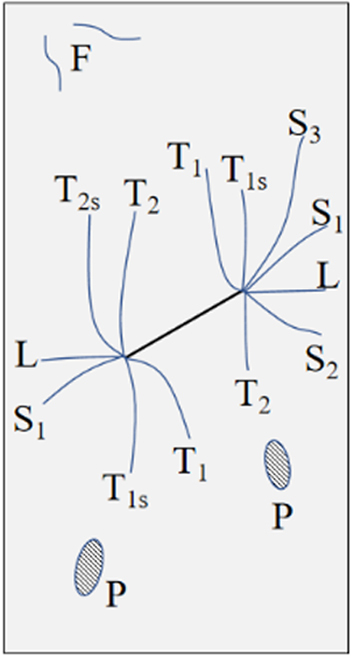

The mechanical properties and failure characteristics of joined rocks have an important impact on the disaster prevention of underground engineering and the sustainable development of mineral resources. The effects of confining pressure, joint location, and joint thickness on the mechanical properties of rock-like specimens under triaxial test have been studied. Furthermore, using the "DFN-age" function of PFC numerical simulation, the stress characteristics, and failure characteristics of rock specimens under different confining pressure, joint location and joint thickness are analyzed. The research results indicate that as the thickness of the joint increases and the joint position approaches the center of the specimen, the compressive strength of the specimen decreases. As the confining pressure increases, the compressive strength increases and failure modes of rock like specimens with different joint types also tend to be similar. The specimens manifest complex shear-tensile composite failures. In addition, the initiation cracks and main control cracks at the joint terminus can be classified as reverse tensile wing cracks, reverse shear cracks, shear cracks and tensile wing cracks. When the joint thickness of the specimen is 1.0mm and the distance from the joint position to the center of the specimen is 10mm~20mm, the crack evolution characteristics and stress distribution law of the specimen will undergo a transformation.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.