Exploring the influence of water film thickness on the yield stress of cement-limestone pastes: a comprehensive analysis

1

Department of civil engineering, Changzhi Vocational And Technical College, China

Submission date: 2024-01-24

Final revision date: 2024-03-20

Acceptance date: 2024-04-09

Publication date: 2025-03-20

Corresponding author

Archives of Civil Engineering 2025;71(1):83-98

KEYWORDS

TOPICS

ABSTRACT

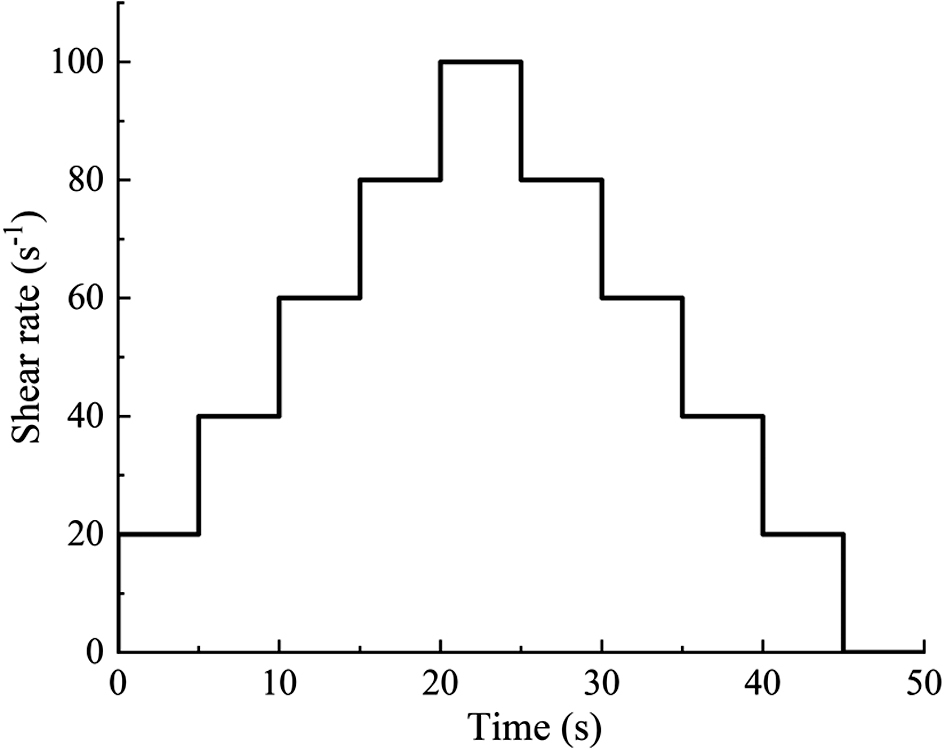

This study delves into the influence of water film thickness (WFT) on the rheological characteristics, particularly the yield stress, of cement paste incorporating limestone powder. Employing an Anton Paar MCR 102 rheometer, precise measurements of both the static and dynamic yield stress were conducted. Artificial neural networks (ANN) were then applied to explore the relationship between WFT and yield stresses. The findings reveal an approximate linear growth pattern in the shear stress-shear rate profile of cement-limestone paste, with an intensified shear thickening observed as limestone powder content increases. The augmentation of limestone powder and specific surface area notably enhances both static and dynamic yield stresses, with the latter reaching 70.26 Pa in the case of a paste containing 50% Class III limestone powder (1088 m2/kg). The WFT of cement-limestone paste particles is contingent on the ratio of solid particle packing density to total specific surface area, exhibiting an increase with rising solid particle packing density. Both static and dynamic yield stresses exhibit a negative correlation with WFT. Artificial neural networks demonstrate efficacy in predicting static and dynamic yield stresses based on mix ratio parameters and WFT, with a higher prediction accuracy for static yield stress, reflected in an R2 value of 0.9745.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.