Study on deformation of layered rock tunnel based on material point method

1

State Key Laboratory of Coal Mine Disaster Dynamics and Control, Chongqing University, China

2

China Construction Third Engineering Bureau Group Co.,Ltd, China

3

Chongqing Expressway Wuyunkai Construction Co., Ltd, Chongqing Expressway Group Co., Ltd, China

4

China State Construction Railway Investment & Engineering Group Co., Ltd, China Construction Third Engineering Bureau Group Co.,Ltd, China

Submission date: 2024-01-23

Final revision date: 2024-04-03

Acceptance date: 2024-04-30

Publication date: 2025-03-20

Corresponding author

Binwei Xia

State Key Laboratory of Coal Mine Disaster Dynamics and Control, Chongqing University, China

State Key Laboratory of Coal Mine Disaster Dynamics and Control, Chongqing University, China

Archives of Civil Engineering 2025;71(1):65-81

KEYWORDS

TOPICS

ABSTRACT

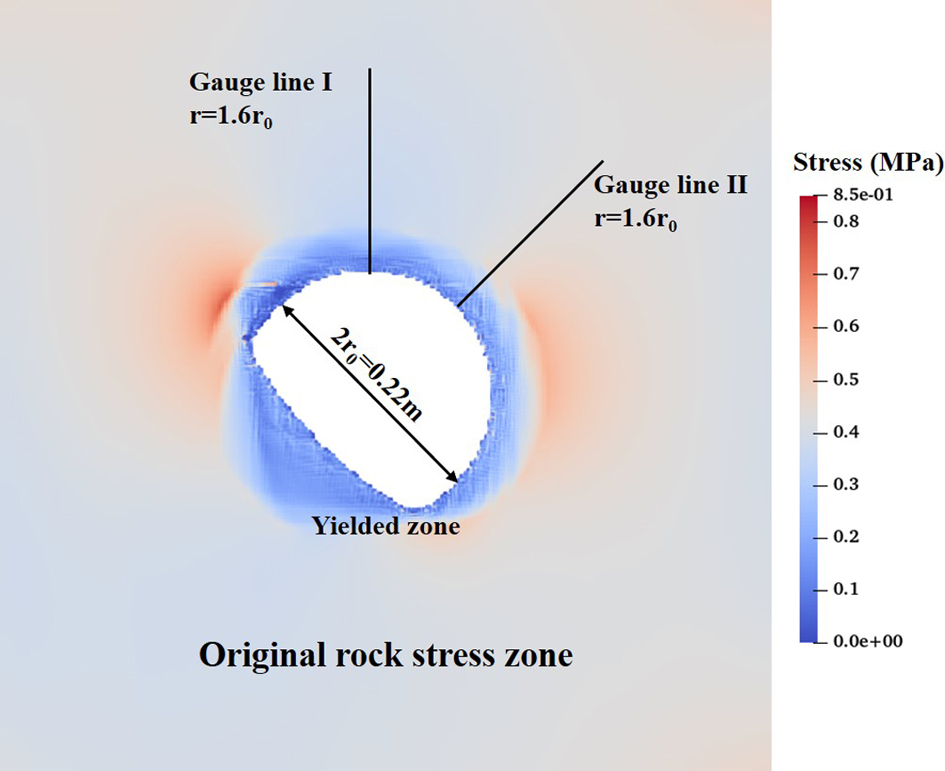

The stability problems of layered rock mass are frequently encountered in tunnel and underground engineering. Affected by bedding plane, the mechanical properties of surrounding rock show obvious anisotropy, which makes its failure characteristics more complicated. Therefore, it is essential to clarify the deformation and damage characteristics of the tunnel in layered rock for the safe and efficient development. In this study, a numerical simulation tool based on material point method and strain softening model is used to establish the plane strain model of tunnel in layered rock, and the deformation process of the tunnel with different dip angles and different rock thickness is studied. The results show that: 1) Compared with the physical simulation test, it is proved that the tool used can simulate the complex process of tunnel deformation and instability, and effectively realize delamination, shear slip and rock fracture in the failure process of tunnel in layered rock; 2) The bedding plane has a significant influence on the failure characteristics of surrounding rock, and the damaged area increases significantly on the bedding plane, cracks are always concentrated in the direction perpendicular to the bedding plane, and the smaller the thickness of the rock layer, the larger the damage area of the surrounding rock; 3) With the increase of joint angle, the number of failure points presents a U-shaped trend, and the decrease of rock thickness will lead to an increase in the number of failure points and a decrease in the percentage of shear failure points.

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.