Stress loading effect research of plastic damage materials based on D-SAP and finite element analysis

1

School of cml Engineering Architecture, Zhejiang Guangsha Vocational and Technical University of Construction, China

2

Department of Technology Development, Dongyang Third Construction Engineering Co., Ltd, China

3

College of Civil Engineering, Zhejiang University of Technology, China

Submission date: 2024-01-26

Final revision date: 2024-03-11

Acceptance date: 2024-03-26

Publication date: 2025-03-20

Corresponding author

Xiaofeng Liu

School of cml Engineering Architecture, Zhejiang Guangsha Vocational and Technical University of Construction, China

School of cml Engineering Architecture, Zhejiang Guangsha Vocational and Technical University of Construction, China

Archives of Civil Engineering 2025;71(1):99-112

KEYWORDS

TOPICS

ABSTRACT

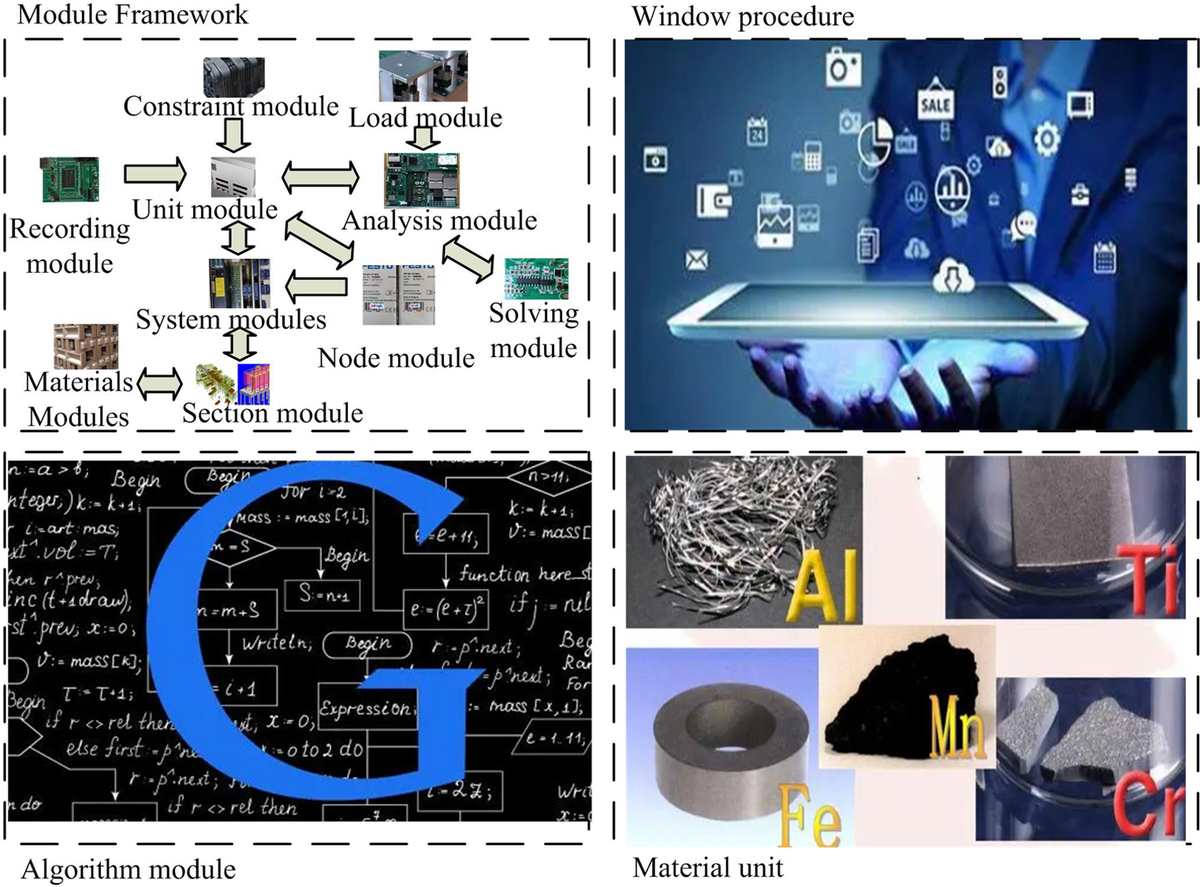

This study mainly analyzes the stress loading effect of current plastic damaged materials and investigates the stress changes during plastic material damage. The stress structure of the material is analyzed using D-SAP software and the finite element analysis. A new analysis system for plastic damage materials is established. The new system can analyze the damage stress and rigidity magnitude of plastic materials. These studies confirm that new system software can to some extent complete the analysis of stress loading effects on plastic damaged materials. The simulation curve of the software is basically consistent with the experimental values. When compared with traditional software for testing, the new software shows significantly better performance in simulating stress situations and accuracy compared to traditional analysis and simulation software. D-SAP and Digimat software show different deviations during testing. D-SAP has the smallest stress variation, while Digimat strain and stress testing has a larger deviation. In the stiffness test, the deviation between the two software is between 2.04% and 5.3%. In multi-axis pressure testing, D-SAP is consistent with the test values. Therefore, the software used in this study has a better effect on analyzing the stress loading effect of the material, and the deviation between the tested stress and stiffness is smaller. This provides a new direction for stress analysis of materials.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.