Assessment of resistance spot welding process quality using modal analysis

1

Welding Centre, Łukasiewicz Research Network - Upper Silesian Institute of Technology, Poland

2

Institute of Fundamentals of Machinery Design, Faculty of Mechanical Engineering, Silesian University of Technology, Poland

These authors had equal contribution to this work

Submission date: 2023-10-16

Final revision date: 2024-01-24

Acceptance date: 2024-02-20

Publication date: 2025-03-20

Corresponding author

Janusz Pikuła

Welding Centre, Łukasiewicz Research Network - Upper Silesian Institute of Technology, 12-14 Karola Miarki, 44-100, Gliwice, Poland

Welding Centre, Łukasiewicz Research Network - Upper Silesian Institute of Technology, 12-14 Karola Miarki, 44-100, Gliwice, Poland

Archives of Civil Engineering 2025;71(1):311-326

KEYWORDS

TOPICS

ABSTRACT

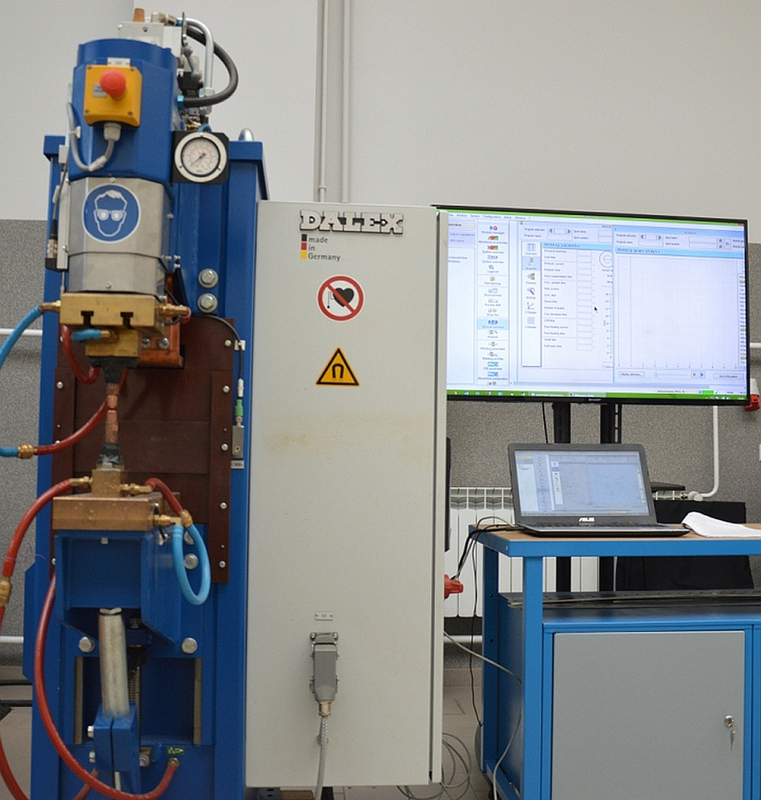

The resistance spot welding is one of the main methods used to join thin-walled metal parts, while a number of factors adversely affect the process and thus the quality of the connections made. This article presents the study results of the possibility of applying modal analysis in the quality examination of welded parts by detecting the missing weld. It was aimed to determine this kind welding process imperfections influence on modal shapes and frequencies by the study of the dynamic properties of welded elements in the frequency domain. The research included real and numerical tests. The proposed testing method for spot welded constructions is a scientific novelty in the world, but the investigation results indicated, that the modal analysis may find application in detecting welding defects such as the lack of the welds.

To assess the quality of the numerical models, the results obtained in the simulation and experimental test results were compared. The analysis involved the first five modes. The mode shapes in relation to the first five modal frequencies identified using the FEM analyses and the experimental tests was consistent with respect to element distortion. The differences indicate the satisfactory conformity of the numerical simulation results with the experimental test results. The article fundamentally demonstrates the applicability of the above-mentioned method to analyse the performance of all welds at once.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.