Properties of one-part CaO-Na2CO3 activated ground granulated blast furnace slag

1

School of Architectural Engineering and Intelligent Construction, HeNan Open University, China

Submission date: 2023-09-09

Final revision date: 2023-10-30

Acceptance date: 2023-12-28

Publication date: 2024-06-19

Corresponding author

Qian Li

School of Architectural Engineering and Intelligent Construction, HeNan Open University, China

School of Architectural Engineering and Intelligent Construction, HeNan Open University, China

Archives of Civil Engineering 2024;70(2):461-476

KEYWORDS

TOPICS

ABSTRACT

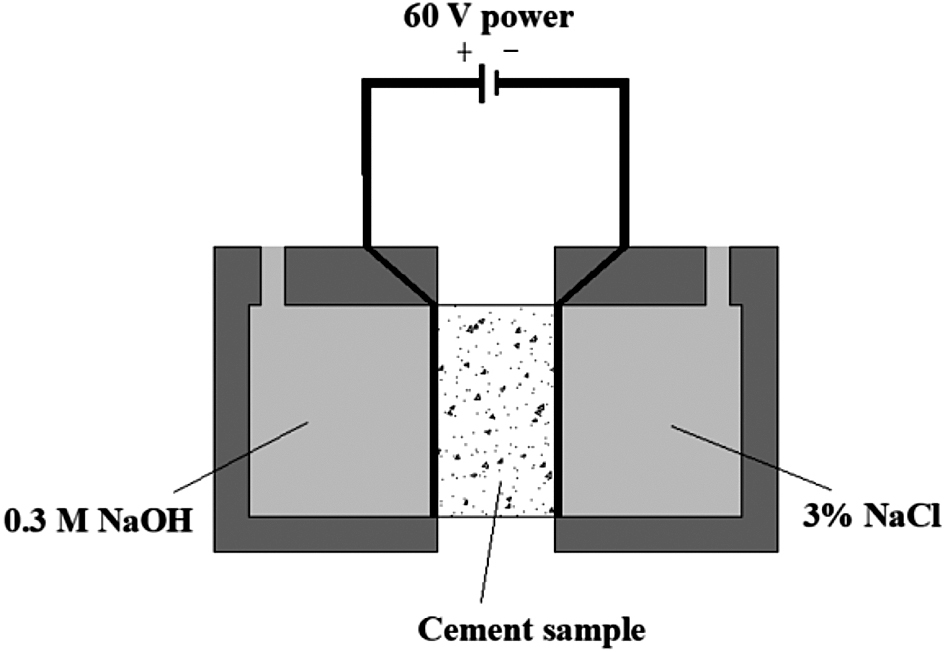

In this study, the fresh and hardened performance and durability of one-part ground granulated blast furnace slags (GGBFS) activated by solid CaO and Na2CO3 were discussed, and their hydration process and microstructure development were analyzed accordingly. Results showed that when the water-to-binder ratio was 0.32, the alkali-activated slag (AAS) paste exhibited lower flowability, higher yield stress and plastic viscosity. As the content of CaO and Na2CO3 increased, the yield stress, plastic viscosity, and compressive strength of AAS after hardening all increased. For the durability of the hardened sample, AAS with high content of activator have higher shrinkage strain and chloride ion flux. The microscopic analysis results indicated that AAS containing CaO and Na2CO3 exhibited more intense hydration heat release and rapid microstructure development in the early stage, thereby promoting the improvement of strength. The use of CaO and Na2CO3 to activate GGBFS has enormous application potential in solid waste utilization and carbon emission reduction, which can reasonably replace traditional Portland cement (PC) as a new generation of sustainable cementitious materials.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.