Post-fire properties of bolt steel, quenched and tempered in the production process

1

Faculty of Civil Engineering, Warsaw University of Technology, Poland

Submission date: 2024-06-26

Final revision date: 2024-10-28

Acceptance date: 2024-10-29

Publication date: 2025-06-16

Corresponding author

Paweł Artur Król

Faculty of Civil Engineering, Warsaw University of Technology, Al. Armii Ludowej 16, 00-637, Warsaw, Poland

Faculty of Civil Engineering, Warsaw University of Technology, Al. Armii Ludowej 16, 00-637, Warsaw, Poland

Archives of Civil Engineering 2025;71(2):429-450

KEYWORDS

exposure timecooling methodhigh-strength steel boltrecovery factorresidual post-fire mechanical propertiesretention factor

TOPICS

ABSTRACT

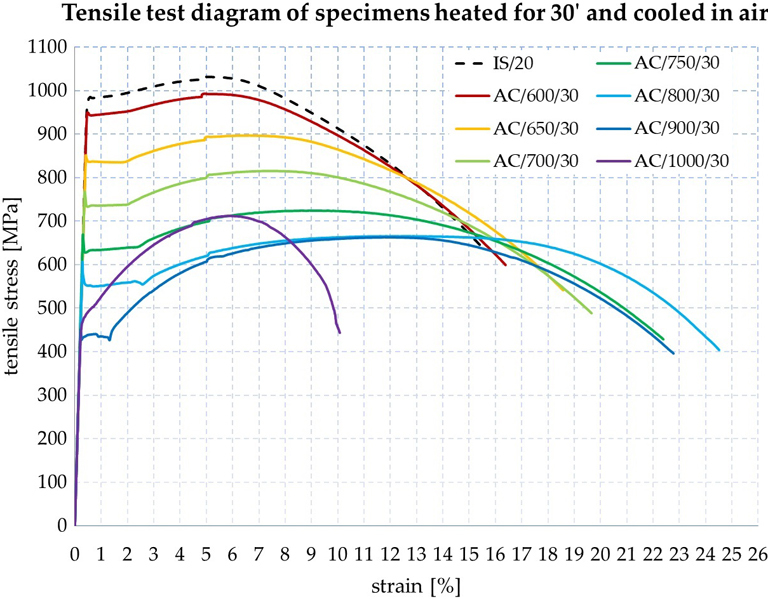

The article presents results of a static tensile test of standardized machined test pieces of round cross-section made of 32CrB3 alloy steel, quenched and tempered in the production process, subjected to environmental actions simulating an extraordinary fire situation. The tests were aimed at assessing the impact of simulated fire conditions on the residual mechanical properties of the analysed steel used to produce grade 8.8 steel construction bolts. The tests involved variants of the maximum temperature applied in the soaking process, exposure time to specific thermal conditions, and the cooling method. The specimens were soaked at temperatures of 600˚C, 650˚C, 700˚C, 750˚C, 800˚C, 900˚C, and 1000˚C for periods of 30', 60', 120' and 240', respectively, and varied cooling methods were applied during the tests. The first batch of specimens, after soaking, was cooled freely at ambient temperature. In the case of the second batch, the specimens were rapidly cooled by immersion in water until they cooled completely, thus simulating the effect of an intensive firefighting operation. The analysis relates to variability of values of the following post-fire parameters obtained in the static tensile test: ultimate tensile strength, yield point, Young's modulus, ultimate strain at maximum force, strain at fracture, percentage elongation after fracture, and percentage reduction of area, depending on the temperature and soaking time, as well as the cooling method applied. The results were compared with those reported in the literature. The values of retention factors and recovery factors were determined.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.