Experimental investigations on mechanical properties of 3D-printed tensegrity-inspired metamaterials based on 4-strut simplex module

1

Wydział Inżynierii Lądowej, Politechnika Warszawska, Poland

Submission date: 2023-10-30

Final revision date: 2023-12-29

Acceptance date: 2024-01-18

Publication date: 2024-10-01

Corresponding author

Archives of Civil Engineering 2024;70(3):343-357

KEYWORDS

TOPICS

ABSTRACT

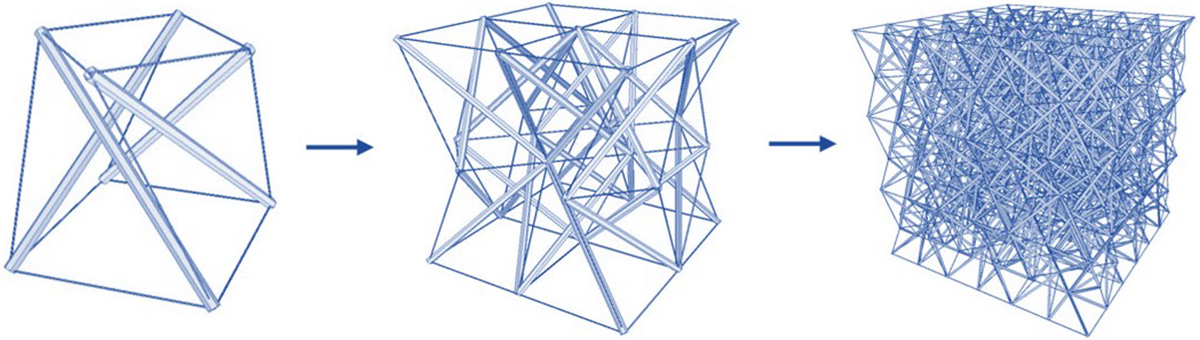

The present study is focused on experimental investigations of mechanical properties of 3D-printed tensegrity-inspired metamaterials. Tensegrity systems have many advantageous features, such as: light weight, high stiffness-to-mass ratio, controllability, inherent attributes of smart structures, and unique mechanical behaviour. They may be applied not only in macro-scale, but they can also be used to create cellular mechanical metamaterials and lattices in various scales. Metamaterials are understood here as human-designed artificial materials, which do not exist in nature, and whose mechanical properties result from the morphology of the inner structure rather than from chemical or phase composition. Experimental studies on tensegrity metamaterials manufactured using 3D printing techniques are hardly present in the literature. This paper presents results of uniaxial compression tests carried out on a number of 3D-printed tensegrity-based modules corresponding to the metamaterial cells, differing in the manufacturing technology, parent material, and size. The following observations were made during the tests: one of the most important parameters that has a direct impact on the results is the elongation at break of the parent material; any inaccuracies at the production stage greatly affect the mechanical behaviour of the structure; it is crucial to ensure a free deformation consistent with the infinitesimal mechanism mode of tensegrity; a post-critical behaviour of the struts was clearly visible in the performed tests.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.