Synchronizing production of precast elements with on-site erection

1

Faculty of Civil Engineering and Architecture, Lublin University of Technology, Poland

2

Faculty of Civil Engineering, Warsaw University of Technology, Poland

Submission date: 2024-02-29

Final revision date: 2024-05-18

Acceptance date: 2024-05-21

Publication date: 2024-10-01

Corresponding author

Piotr Jaśkowski

Faculty of Civil Engineering and Architecture, Lublin University of Technology, Nadbystrzycka 38d, 20-618, Lublin, Poland

Faculty of Civil Engineering and Architecture, Lublin University of Technology, Nadbystrzycka 38d, 20-618, Lublin, Poland

Archives of Civil Engineering 2024;70(3):607-618

KEYWORDS

TOPICS

ABSTRACT

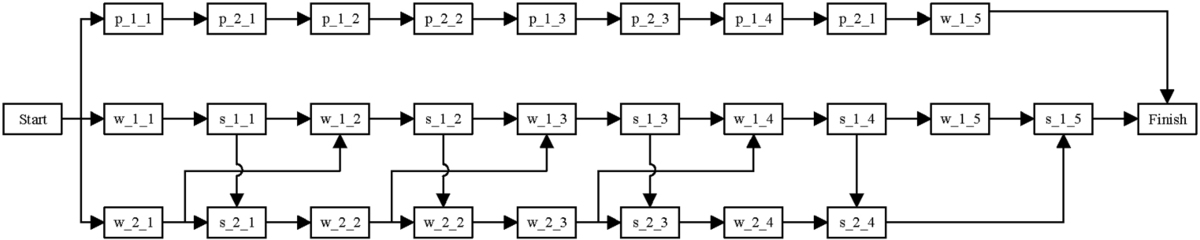

Offsite construction technologies are developed to reduce project cost and duration. To make the most of the potential offered by prefabrication the planner should consider the whole supply chain. A failure to coordinate the off-site production with on-site erection is a source of waste (waiting time of the construction crews or redundant handling activities on-site). Most of the research to date focused on optimizing operations of a prefabrication plant assuming a deterministic schedule of demand for its products. The purpose of this paper is to develop a mathematical model for integrated scheduling of offsite and on-site operations. Its solution is a schedule that minimizes the downtime of both the prefabrication plant and the on-site erection crews. In accordance with the Just-in-Time concept, the prefabrication schedule is set in a way to reduce the stocks of finished products, thus reducing the storage area and cost of funds tied up in inventory. The schedule’s robustness against the disturbance in the production and erection workflows is assumed to be assured allocating time buffers. The advantage of the proposed method is the ease of collecting the input: instead of detailed cost records, estimates of unit cost of lost time can be used.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.