Seismic energy dissipation performance of anti-buckling bracing and component composition parameters analysis

1

Department of Architecture and Civil engineering, Zhejiang Tongji Vocational College of Science and Technology, China

2

College of Civil and Transportation Engineering, Hohai University, China

3

JSTI GROUP, China

Submission date: 2023-12-12

Final revision date: 2024-03-02

Acceptance date: 2024-04-23

Publication date: 2025-03-20

Corresponding author

Wei Zhang

Department of Architecture and Civil engineering, Zhejiang Tongji Vocational College of Science and Technology, China

Department of Architecture and Civil engineering, Zhejiang Tongji Vocational College of Science and Technology, China

Archives of Civil Engineering 2025;71(1):577-594

KEYWORDS

performance analysisbuckling-restrained bracehysteresis performancehysteresis curvecomponent parameters

TOPICS

ABSTRACT

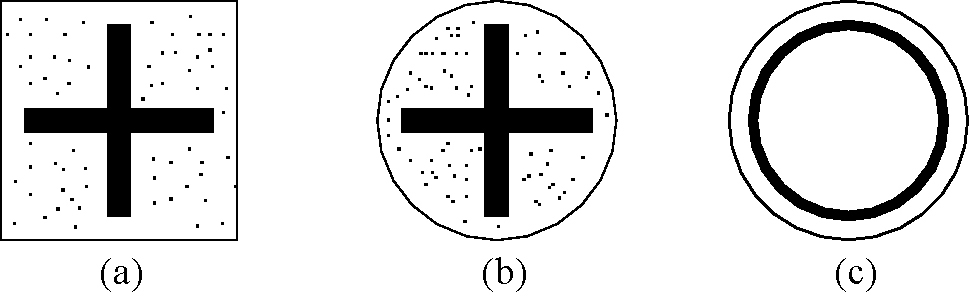

Through the finite element method, the finite element models of three kinds of buckling-restrained brace components : cross-shaped square steel tube support, cross-shaped circular steel tube support and circular steel tube support are established. The hysteretic performance of buckling-restrained braces under cyclic loading is analyzed, and the influence of component parameters on the mechanical performance of three kinds of buckling-restrained braces is further analyzed. The results show that the three types of buckling restrained braces have good hysteretic energy dissipation performance, and the cross-shaped square steel tube brace has the best hysteretic energy dissipation performance. The influence of the restraint stiffness ratio of the buckling-restrained brace on the mechanical properties of the three types of buckling-restrained braces is consistent. With the increase of the restraint ratio, the buckling-restrained brace reaches full-section yield. The increase of the width-thickness ratio of the inner core element will cause the yield lag of the buckling-restrained brace, while the lower width-thickness ratio of the inner core element will cause excessive stress concentration. Therefore, it is suggested that the width-thickness ratio of the inner core element should be between 5 and 10. The initial imperfection and connection stiffness of buckling-restrained braces have little effect on the bearing capacity of buckling-restrained braces.

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.