Possibility of assessing cements with non-clinker constituents in terms of alkali reactivity with silica aggregate

1

Faculty of Civil Engineering and Architecture, Kielce University of Technology, Poland

These authors had equal contribution to this work

Submission date: 2024-12-19

Final revision date: 2025-07-09

Acceptance date: 2025-07-22

Publication date: 2025-12-01

Corresponding author

Przemysław Jan Czapik

Faculty of Civil Engineering and Architecture, Kielce University of Technology, Al. Tysiąclecia Państwa Poslkiego 7, 25-314, Kielce, Poland

Faculty of Civil Engineering and Architecture, Kielce University of Technology, Al. Tysiąclecia Państwa Poslkiego 7, 25-314, Kielce, Poland

Archives of Civil Engineering 2025;71(4):605-615

KEYWORDS

TOPICS

ABSTRACT

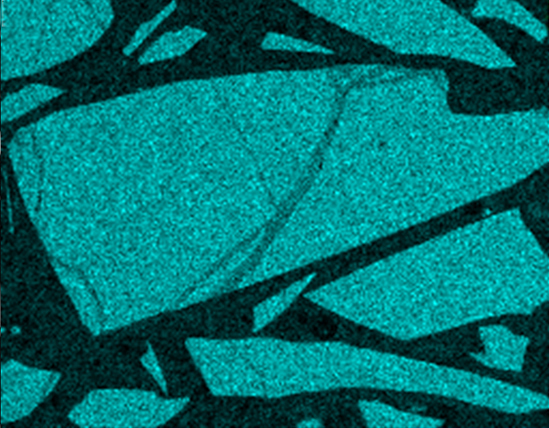

This paper presents the results of a study investigating the influence of non-clinker constituents in cement on the risk of deleterious alkali-silica reaction (ASR). The cements selected for this study were CEM II types containing commonly used non-clinker constituents, such as ground granulated blast furnace slag (GGBS) and silica fly ash. Additionally, a binder was prepared by mixing CEM I cement with metahalloysite in a 3:1 ratio. As a reference, CEM I cements without non-clinker constituents were used. Expansion tests were conducted on mortars using standard reactive aggregate (borosilicate glass cullet) according to ASTM C 441. The results, evaluated against the criteria outlined in ASTM C 1157, demonstrated that the binders with non-clinker constituents met the “Option-R” requirement. The expansion of, mortars made with cements containing non-clinker constituents was significantly reduced compared to mortars made with pure Portland cement. The most significant effectiveness in this regard was achieved with the metahalloysite cement. The obtained expansion results correlated well with the microstructural changes in the mortars, which can be linked to the occurrence of ASR. The microstructure of the mortars was examined using scanning electron microscopy..

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.