Investigating the influence of weak acid salt agents in mixture and curing conditions on the properties of supersulfated cement mortar

1

Faculty of Materials Technology, Ho Chi Minh City University of Technology - VNU-HCM, Viet Nam

2

Centre of Excellence Geopolymer and Green Technology (CEGeoGTech), Universiti Malaysia Perlish (UniMAP), Malaysia

3

School of Engineering and Technology, Walailak University, Thailand

4

Department of Physics, Faculty of Production Engineering and Materials Technology, Czestochowa University of Technology, Poland

Submission date: 2023-10-28

Final revision date: 2024-02-05

Acceptance date: 2024-02-13

Publication date: 2024-10-01

Corresponding author

Nguyen Khanh-Son

Faculty of Materials Technology, Ho Chi Minh City University of Technology - VNU-HCM, Ly Thuong Kiet street, 70000, Ho Chi Minh city, Viet Nam

Faculty of Materials Technology, Ho Chi Minh City University of Technology - VNU-HCM, Ly Thuong Kiet street, 70000, Ho Chi Minh city, Viet Nam

Archives of Civil Engineering 2024;70(3):545-559

KEYWORDS

TOPICS

ABSTRACT

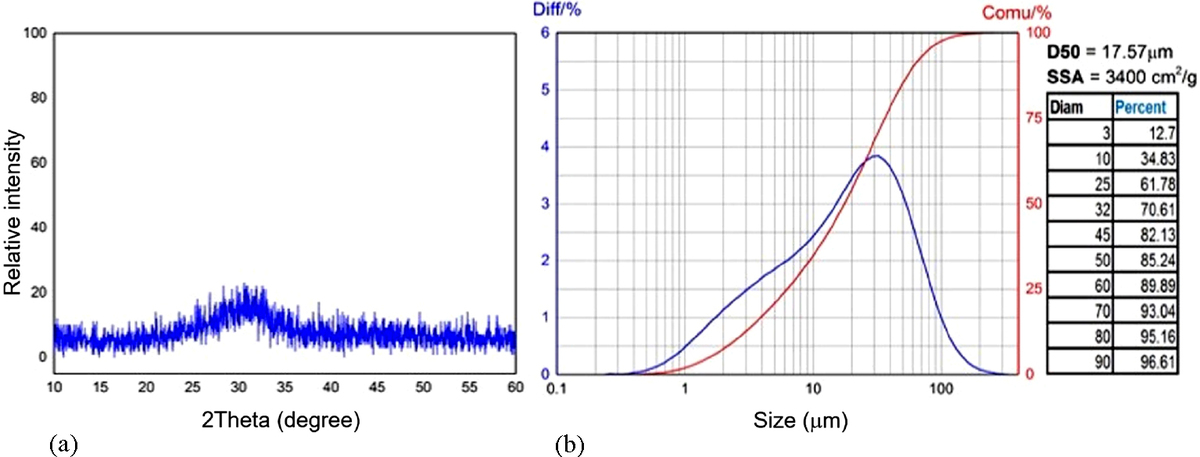

Supersulfated cement (SSC) is a specialized cement comprising ≥75%wt granulated blast-furnace slag (GBFS), 5-20%wt calcium sulfate (gypsum or anhydrite), and ≤ 5%wt Portland cement clinker. SSC exhibits exceptional performance, including high resistance to sulfate solutions, peaty acids, oils, and other contaminants in wastewater and soil. Furthermore, its high slag content, surpassing 75%, contributes to reduced CO2 emissions, making SSC an environmentally sustainable choice for cement production. This study investigates the effects of weak acid salt agents (citrate and tartrate) added during mixture preparation, as well as different curing conditions, on the properties of SSC mortar. Different material characterization techniques were employed to perform a comprehensive analysis of the phase assemblage, such as X-ray diffraction (XRD) and scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS). The results demonstrate the abundant ettringite (E) formation in the hydrated cement product, particularly when exposed to rich sulfate ion solutions. Additionally, the research highlights the significant impact of temperature-stimulated curing conditions on accelerating the hydration reaction of SSC. These experimental findings provide deeper insights into the factors influencing SSC's hardening and strength development. The findings of this study provide valuable information for enhancing the efficiency and usage of SSC in the construction industry, which aligns with the goal of sustainable development.

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.