Performance evaluation of hot mix asphalt (HMA) using glass fiber as a partial replacement of fine aggregate

1

Faculty of Civil Engineering Technology, Universiti Malaysia Perlis, Malaysia

2

Universiti Malaysia Perlis, Centre of Excellence Geopolymer and Green Technology (CEGeoGTech), Malaysia

3

Department of Physics, Faculty of Production Engineering and Materials Technology, Czestochowa University of Technology, Poland

These authors had equal contribution to this work

Submission date: 2023-10-29

Final revision date: 2024-03-07

Acceptance date: 2024-05-07

Publication date: 2025-03-20

Corresponding author

Archives of Civil Engineering 2025;71(1):403-413

KEYWORDS

TOPICS

ABSTRACT

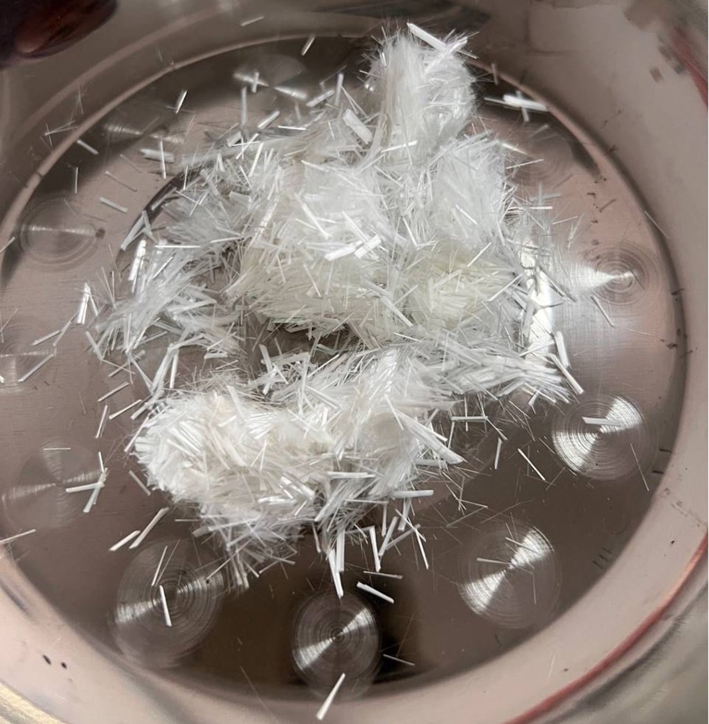

Hot Mix Asphalt mixtures are often used as the top layer of pavement structures to build roads worldwide. Hot Mix Asphalt (HMA) mixtures combine bitumen and aggregate to produce roads. This paper aims to determine the optimum bitumen content (OBC) and investigate combining glass fiber in HMA with replacing a partial glass fiber of fine aggregate by Marshall Stability. The Hot Mix Asphalt was produced by mixing aggregate with 4% to 6% bitumen to obtain OBC to use in Hot Mix Asphalt Modified with glass fiber. Meanwhile, HMA modification was produced by mixing aggregate and OBC bitumen with 1% to 6% replacement glass fiber as a partial fine aggregate to improve the properties of Hot Mix Asphalt (HMA). Marshall Stability test, Aggregate Impact Value (AIV), Aggregate Crushing Value (ACV), Penetration Point, and Softening Point test was conducted. The effects of glass fiber in terms of stability, flow, stiffness, void in the total mix and void-filled bitumen in Marshall stability are investigated and compared with the control sample. The Optimum Bitumen Content (OBC) using Marshall Stability was chosen at 4.7% as OBC due highest stability value and passed in requirement standard JKR 2008. After analysis, the stability obtained for HMA Modified showed that adding 1%, 2%, and 3% glass fibers contributed to the highest stability values and passed the standards of parameters required by JKR 2008. Therefore, this paper can be concluded that the presence of glass fibers can significantly improve the performance of Hot Mix Asphalt (HMA).

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.