Nucleation and growth rate determination on alkali-activated slag under various sodium hydroxide molarity

1

Faculty of Chemical Engineering and Technology, Universiti Malaysia Perlis, Malaysia, Malaysia

2

Geopolymer& Green Technology, Centre of Excellence (CEGeoGTech), Universiti Malaysia Perlis (UniMAP), Universiti Malaysia Perlis. Malaysia, Malaysia

3

Faculty of Civil Engineering and Technology, Universiti Malaysia Perlis, Malaysia, Malaysia

4

Faculty of Mechanical Engineering and Technology, Universiti Malaysia Perlis,Malaysia, Malaysia

5

Department of Physics, Faculty of Production Engineering and Materials Technology, Czestochowa University of Technology, al. ArmiiKrajowej, Poland

Submission date: 2023-10-29

Final revision date: 2024-01-09

Acceptance date: 2024-01-30

Publication date: 2024-10-01

Corresponding author

Rosnita Mohamed

Faculty of Chemical Engineering and Technology, Universiti Malaysia Perlis, Malaysia, 02600, Kangar, Malaysia

Faculty of Chemical Engineering and Technology, Universiti Malaysia Perlis, Malaysia, 02600, Kangar, Malaysia

Archives of Civil Engineering 2024;70(3):473-485

KEYWORDS

Alkali-activated slagheat evolutionJohnson Mehl Avrami Kolmogrov modelmolarity of sodiium hydroxidenucleation and growth rate

TOPICS

ABSTRACT

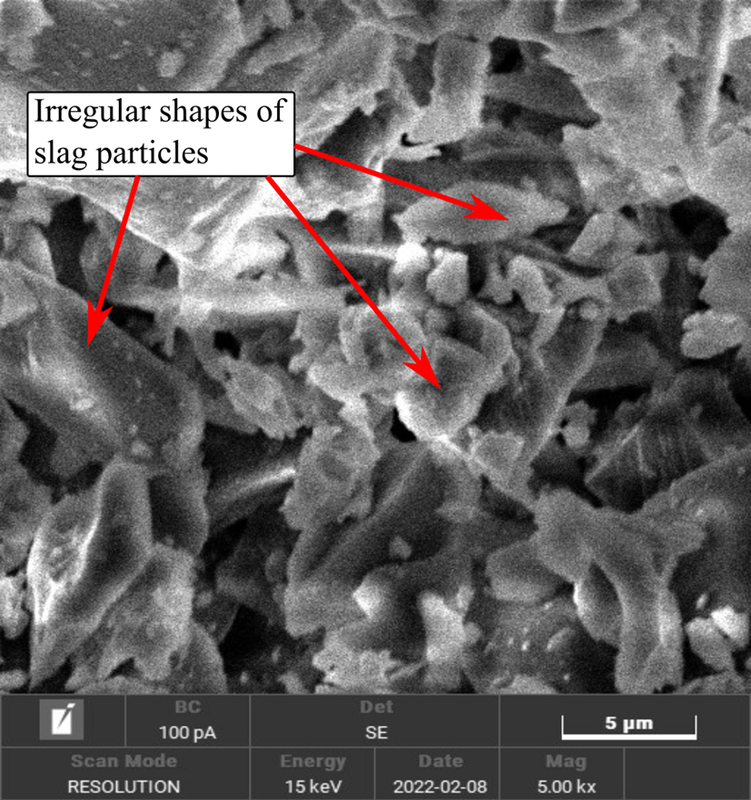

Alkali-activated slag has been noted as one of potential alternatives to the ordinary Portland cement due to its properties including high early strength performance and capability of ambient curing. However, there is still limited studies available on elucidating the reaction processes towards producing the excellent properties. This study aims to elucidate the mechanism of alkali activation of slag under different molarities of sodium hydroxide, which is one of the most influential factors on the properties of alkali-activated slag. Heat evolution of alkali-activated slag was used as a real-time monitoring technique. For mix designation, the molarity of sodium hydroxide was varied from 6M to 14M, with solid-to-liquid ratios of 0.6 and alkali activator ratios of 2.0 remaining constant. The calorimetric data obtained was further used for determination of degree of reaction, nucleation and growth rate mechanism using Johnson-Mehl Avrami Kolmogrov model. According to the findings, it was found that regardless of various molarity of sodium hydroxide applied, the nucleation mechanism and growth is governed by instantaneous heterogeneous nucleation with rod-like growth as the n value is approaching 1 in which is observed from the morphology of the alkali-activated slag at lowest molarity applied (6M). Furthermore, increasing in molarity of sodium hydroxide was found to decrease the total heat evolved and the lowest was obtained when using 14M.

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.